When success hinges on your parts supplier

Serving the Automotive Tier 1 and Appliance OEM customers with manufacturing excellence. Please allow us to serve you with our expertise and attention to detail.

Sisler's Global Footprint

USA Mexico Italy Taiwan Vietnam

Sisler's Global Footprint

WORLD WIDE

USA Mexico Italy Taiwan Vietnam

About Sisler Manufacturing Group

About Sisler Manufacturing Group

Read more about Sisler Manufacturing Group by clicking the red titles below. You will find more in-depth information about our Company History, Mission, Values & Vision, 6D Methodology, 5S & our Company Culture.

Sisler Capabilities

Sisler Capabilities

Progressive die stamping, central lubrication

Robotic, MIG & Resistance

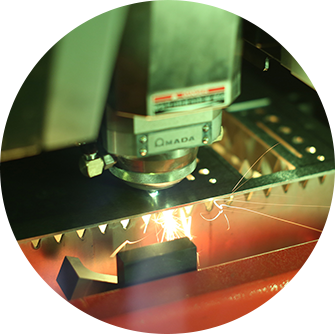

Sheet Metal Fabrication Division

Supply millions of hinge assemblies per year for major OEM’s

Full PPAP Develoment, Tool Design & Development

Automated Final Assembly Process

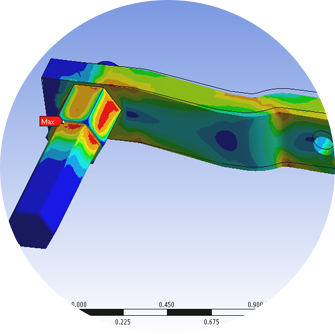

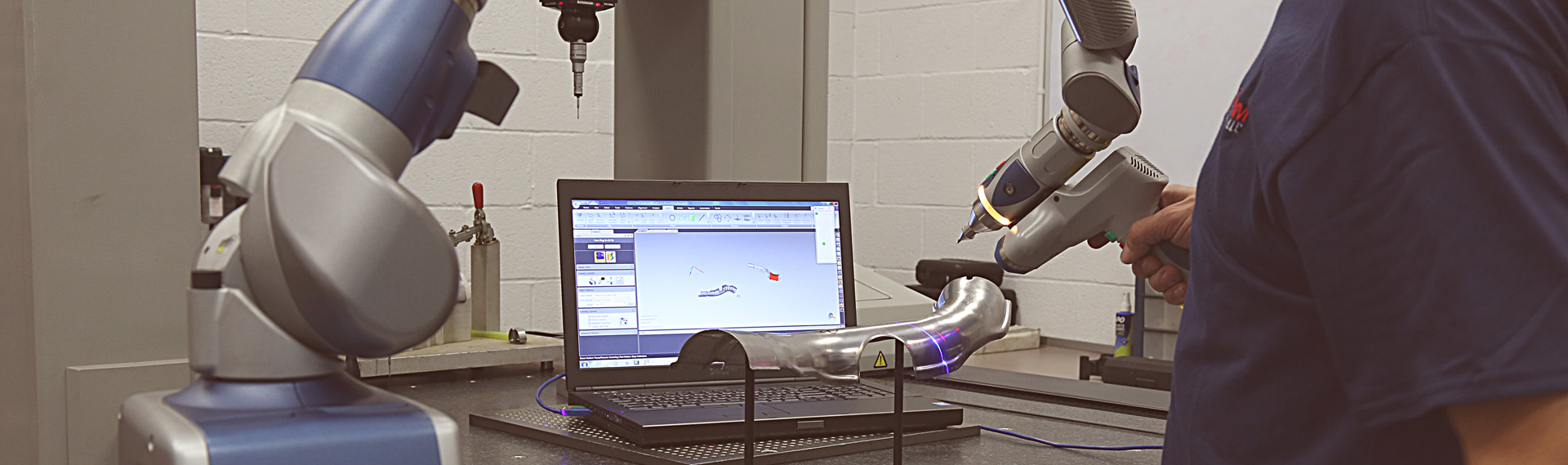

Engineering Technologies

We provide complete APQP process support using widely known development tools to achieve the 1.67 Cpk results.

We provide complete dimensional metrology support for PPAP requirements measuring using customer required GD&T or linear measurements.

Our process control includes hardware pushout testing as well as material qualification using an Instron Tensile tester.

A craftsman is only as good as his tools, with this saying we maintain a comprehensive software library to assist our engineering teams in helping our customers.

Our engineering group and test lab working through the customer can develop products and test plans to guarantee success and survivability in final customer environments.

Our team of tooling engineers with our tool and die makers help maintain our zero defect performance.

Quality

Certifications

Download IATF 16949 Certification

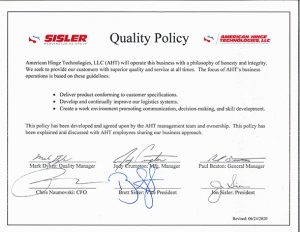

Download American Hinge Technology Quality Policy

Download Truform Quality Policy

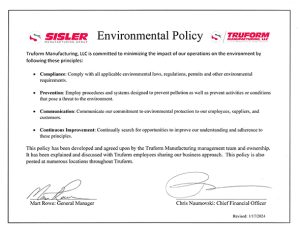

Download Truform Environmental Policy

Business Unit Profiles

Business Unit Profiles

Strategic Business Alliances

Strategic Business Alliances

News and Updates

New and Updates

Read our entire Sisler Manufacturing News Archive.

Congratulations to the 11 winners of the perfect attendance award for the month of January 2022! L to R: Larry Baker, Norma Weatherspoon, Kimberly Scales, Justin Talley, James Weatherspoon, Nick Schmittou, Brian Carter, Tim Claxton, BJ Slater, Anita Paris, and Cheryl BarnesRead More »

Congratulations to the 11 winners of the perfect attendance award for the month of January 2022! L to R: Larry Baker, Norma Weatherspoon, Kimberly Scales, Justin Talley, James Weatherspoon, Nick Schmittou, Brian Carter, Tim Claxton, BJ Slater, Anita Paris, and Cheryl BarnesRead More » Congratulations to the nine employees who received awards for Perfect Attendance during the month of February, 2022! L to R: Greg Meredith, Steven Smith, Sam Hannah, Aaron Cates, Luke O’Guin, Anita Paris, Tim Claxton and Cheryl Barnes. Read More »

Congratulations to the nine employees who received awards for Perfect Attendance during the month of February, 2022! L to R: Greg Meredith, Steven Smith, Sam Hannah, Aaron Cates, Luke O’Guin, Anita Paris, Tim Claxton and Cheryl Barnes. Read More » The Truform Quality Award Program is given to our hourly employees based on our customer’s weekly feedback related to quality satisfaction. The following employees were awarded prizes for the recent Quality Awards. L to R: Shay Bowen, Kimberly Scales, Jay Owen, Anita Paris, Justin Talley, Hared Hall, Michelle Voelz, and Greg MeredithRead More »

The Truform Quality Award Program is given to our hourly employees based on our customer’s weekly feedback related to quality satisfaction. The following employees were awarded prizes for the recent Quality Awards. L to R: Shay Bowen, Kimberly Scales, Jay Owen, Anita Paris, Justin Talley, Hared Hall, Michelle Voelz, and Greg MeredithRead More »- Truform AHT inspects its latest “state of the art” assembly line Truform / AHT personnel were recently on site in Italy running off their latest “high-tech” hinge assembly line. This equipment was developed under the expert guidance of Nuova Star Spa the world leaders in hinge technology!Read More »

- Great job to the chefs doing the cooking!Read More »

Congratulations to the 11 winners of the perfect attendance award …Read More »

Congratulations to the 11 winners of the perfect attendance award …Read More » Congratulations to the nine employees who received awards for Perfect …Read More »

Congratulations to the nine employees who received awards for Perfect …Read More » The Truform Quality Award Program is given to our hourly …Read More »

The Truform Quality Award Program is given to our hourly …Read More »